SPS Technologies, a world-leading specialist fasteners, assemblies and precision components manufacturer for the aerospace sector has increased productivity by 23%, which equates to 273 additional productive hours per week across 15 machines, after utilising smart technology from FourJaw Manufacturing Analytics.

Employing 335 people at its site in Leicester, UK, SPS Technologies operates as part of PCC Fasteners, one of the world’s largest manufacturers of critical fastening systems for aerospace and defence applications, including power generation, wind turbines, marine, and performance motorsport.

With increasing inflationary cost pressures, skills shortages and longer lead times for machinery and equipment, the company challenged itself to increase the overall productivity of its manufacturing operations. The business was looking for an overall uplift in output by 50% by the middle of 2024.

With increasing inflationary cost pressures, skills shortages and longer lead times for machinery and equipment, the company challenged itself to increase the overall productivity of its manufacturing operations. The business was looking for an overall uplift in output by 50% by the middle of 2024.

To achieve the 50% uplift, the business recognised it needed to engage in a number of strategic projects. Whilst the management team acknowledged that they needed to invest in more machinery and people, they recognised that they also needed to ensure they were getting the most they could out of their current asset base.

Initially, the team set an objective to increase machine utilisation by two-per-cent which would reduce overall labour costs by around £10,000 per month and to achieve this, they turned to the manufacturing analytics platform, FourJaw.

Richard Baker, Continuous Improvement Manager at SPS Technologies said: “Increasing productivity is a key lever to help offset inflationary increases and keep pace with demand. Finding a solution that could help us increase throughput before looking to purchase new equipment, which itself is a time-consuming and costly exercise, to maximise the output of our current machines was vital.”

“To increase productivity, we needed to understand how productive machines were and what opportunity for improvement was available. To achieve this, we required accurate and timely data from our equipment. It soon became apparent that we would require the assistance of a technology platform to work with our machines, which would be easy to roll out across the factory floor to deliver a ‘near-instant’ measure of efficiency.”

“Real-time data would be the key to removing time-consuming, labour-intensive processes, freeing up team leaders and managers. By identifying inefficiencies, we could proactively make process changes to increase productivity. The data would not only have an immediate impact on production capacity but also help our business strategy decision-making process.”

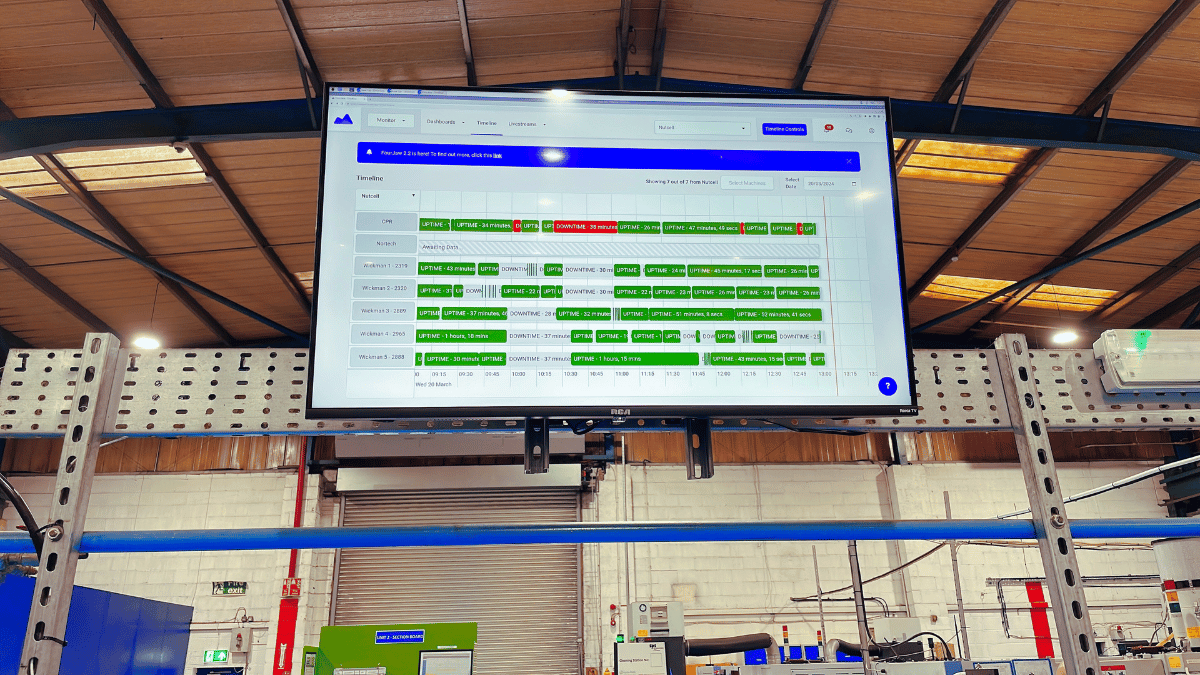

Having reviewed multiple solution providers, SPS Technologies chose an IoT hardware and cloud-based machine monitoring solution from FourJaw Manufacturing Analytics, starting with a trial of 10 machines over six months and thanks to its success, SPS has recently rolled FourJaw out further, bringing the total number of machines being monitored to 50.

The impact of the technology has been significant: it removed inefficiencies in procedures, improved communication between the machine operators and the inspection lab, reduced downtime awaiting results of critical inspection processes, increased shift capacity by planning and scheduling work more efficiently, and improved cross-department cooperation which ensures problems are identified immediately and support is given to keep machines operational.

“Our technology monitors each machine, regardless of its age, brand or function, to reveal when and why it is not being utilised to its full capacity. This information is made available in real-time so that machine operators and managers can work together to identify issues, understand bottlenecks and inefficiencies, and resolve them much more quickly to get production back on schedule” stated Chris Parkin, Head of Customer Success at FourJaw.

“Another benefit of the technology has been how it’s improved communication. SPS has its manufacturing spread across two factories, which historically has presented communication challenges and inefficiencies. FourJaw has removed these issues as it allows operators to communicate much easier and quicker than the previous methods used. Our technology provides insight so that areas for improvement and decisions can be made based on fact rather than gut feeling. It’s fantastic to see what Richard and the team at SPS have achieved so far with the technology and it’s testament to how well the cultural adoption has gone as they continue to roll out the technology across the factory.”

Richard at SPS adds: “All of these activities have led to an increase in machine productivity of 23% which equates to 273 additional productive hours per week on the machines that have the platform running, which we see as a significant result for the business operationally and commercially.”

“The solution provider, FourJaw Manufacturing Analytics, worked with us to implement a ‘trial’ of the technology across 10 of our machines over six months, the technology is now on 50 machines. Key stakeholders from SPS worked and continue to work closely with FourJaw’s implementation team, which has made rolling out the technology, both technically and culturally much easier than we were expecting. The project was led by the Continuous Improvement function with SPS, however, importantly a cross-functional team across all operations, from shopfloor operators to the General Manager were part of the project team and all interested in delivering positive results for the business. Getting this cross-functional stakeholder buy-in as early as possible resulted in high levels of engagement which has resulted in getting an immediate benefit from the technology.”

SPS Technologies has more than 200 different machines across the two factories. The team is now looking at a further rollout to take place in stages throughout 2024 to deliver a similar return on investment they have achieved so far and support their overall business strategy.